Biodegradable Packing Peanuts Making Machine

Packing peanuts are small pieces of Styrofoam used to fill up space, provide cushioning, and help prevent shock in moving boxes. They can also be used as filler so objects don't slide around and are great for use in between a second layer of boxes for extra protection.

Environmentally friendly and degradable, completely replace plastic foam, widely used in packaging and construction industries

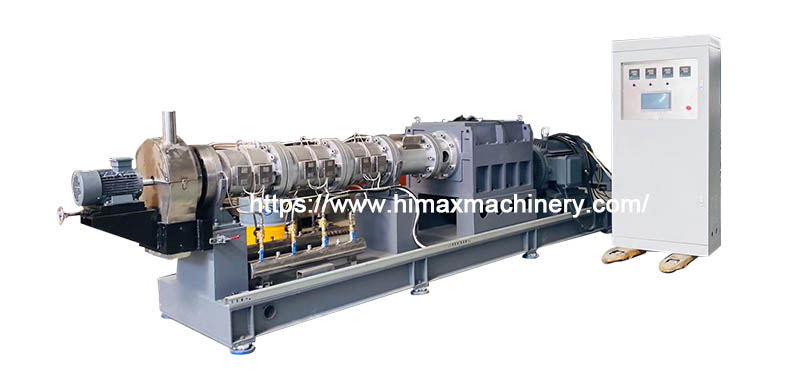

Biodegradable Packing Peanuts Making Machine

Biodegradable packing peanuts machine uses cornstarch/tapioca starch as raw materials, and produces biodegradable packaging materials with diverse uses and high value through the twin-screw extruder heat treatment process. It has the characteristics of non-toxic, harmless and biodegradable. It will melt when it meets water, and will not affect the ecological environment. It is very environmentally friendly.

The packing peanuts making machine is made of food-grade stainless steel. The production line has reasonable design, uniform output, and high automation, which reduces labor costs and improves production efficiency; it can be customized according to customer service needs, and we will provide high-quality after-sales service.

Raw materials

Natural starch, like corn starch, cassava starch, tapioca starch etc

Finished product

Technical parameter

Model | HM65 | HM70 | HM85 | HM90 | HM120 |

Capacity | 100-150kg/h | 200-260kg/h | 300-500kg/h | 500-600kg/h | 1t/h |

Configuration advantage

Siemens PLC programmable, touch screen control.

Special coupling mechanism to reduce the mechanical impact at the moment of cutting.

The barrel contains a circulation channel, which can be fed with steam or water.

Equal proportional flow control of Sparsak valve water.

Optional density controller.

Our service

Sales representatives will provide you with professional consultation on market, equipment, process, raw materials, packaging and other aspects.

Assist you in equipment selection, process design, and plant optimization layout.

Compensation schemes for raw material changes can be designed for your products, and on-site demonstrations can be made.

According to your needs, special design, manufacture and application test can be carried out, and targeted training can be provided.

Design a reasonable packaging and transportation plan for you, arrange transportation on behalf of you, send technical personnel to install and debug, and train personnel.

The equipment is guaranteed for one year, and spare parts are supplied at long-term discounts.

Undertake the design and processing of similar imported equipment parts.