HM35-IV Lab twin-screw Extruder

-Application: For colleges and universities, research institutes and large enterprises Medium-sized enterprises are engaged in all kinds of extrusion, extrusion maturity, extrusion variation research universal model.

-Certification: CE, ISO9001, SGS

-Delivery Time: Around 30 working days

Technical parameter of laboratory extruder

No. | Item | Details | No. | Item | Details | |

1 | Engine power | 7.5KW | 15 | Temperature precision | ±1.0℃ | |

2 | Engine speed-control | Frequency speed-control | 16 | Number of measuring temperature point | 3 points | |

3 | Screw(2nos) diameter | ∮35mm | 17 | Output | 10-25KG/H | |

4 | Matching screw (one set): | Extruding and expanding vegetable protein screw | 18 | Material of cover | SUS 304 | |

5 | Screw central distance | 26mm | 19 | Pressure scope | 0-30MPa | |

6 | Speed range | 0-500rpm | 20 | Pressure precision | 0.1MPa | |

7 | Screw mode | Building block-combined type | 21 | Number of measuring pressure point | 1 point | |

8 | First series L/D | 11.6:12.7:23 | 22 | Model cooling way | Model Water | |

9 | Second Series L/D | 9.3 : 15: 20.6 | 23 | Number of raw material feeding point | 1 | |

10 | Length of screw | 750mm | 24 | Number of water feeding point | 3 | |

11 | Material of screw | 38CrMoAl nitriding treatment | 25 | Filling Intake | 3 | |

12 | Heating way | Electricity Heating | 26 | Water Intake | 3 | |

13 | Cooling way | Water Cooling | 27 | Raw material Water Percentage Acceptance | 6-70% | |

14 | Temperature scope | 20℃-300℃ | 28 | Raw material percentage Acceptance | 25% |

Advantage:

1、The modular screw :

The machines are equipped with a variety of screw modules, the first transmission with a single-unit, duplex transmission modules, small pitch transmission unit, the transportation unit pitch, anti-helix, shear block, the resistance Central, inserts, Metrology Group, according to different needs arbitrarily design screw portfolio, as long as you think of it, there may portfolio。

2、Assembled Barrel :

The aircraft extinguishers assembled cones contain four sections of the aircraft assembled, which drew about big around can be arbitrarily changing positions. Transformation through the feed tube of mouth can be very convenient location in a screw on the transformation from a number of aspect ratio. Experimental aspect ratio is an important parameter equipment, and general equipment to change the aspect ratio is very difficult, Even though many changes have replacement parts, and this machine has three feed mouth, simply change feed location can conjure up a : 11.6,1:12.7,1:23 aspect ratio of the three, adjust barrel, to change the composition of barrel can be very convenient one : 9.3,1:15,1 : 20.6 aspect ratio of the three.

3、Three feed:

For a special experiment in addition to the ingredients of various components will be added to the list, there are some to be added to the list sooner or later. At this time you can from the first, second, third mouth to feed and in order to control raw materials stay time in the tube. also Can use metering pump press liquid raw materials from the second and third Feed into it.

4、Two-way temperature control:

Laboratory equipment should meet the requirements of different temperatures, Extrusion is a process generated heat, the heat sometimes less than the required calories, Sometimes the heat is greater than the necessary calories, and some segments need high temperature, some segments need low temperature, The drum machine is divided into four sections, the whole course with heating and cooling bidirectional control ,and ensure that achieved the requirements temperature.

In the mold also used two-way heating and cooling control, to control the Expanded in the export of raw materials , or just a maturation without puffing.

5、The three pressure points :

The pressure is also important experimental parameters, and most equipment only located a point of pressure close outlet , can not understand the pressure on every stage, especially for a new combination of the screw hard to imagine all of the pressure distribution. The machines in three different locations can be measured pressure.

6.Moisture wide range of raw materials :

Most equipment to the raw materials are subject to certain restrictions, had little water can not be extruded out, too much water can’t enter extruder, and raw materials can not contain high oil, because the machine have three feeding port, Moisture content can range from 6% -- 70% ,oil content can reach more than 25%

7.Screw speed and wide temperature range :

screw speed arbitrary adjustments between 0-500 RPM. temperature arbitrary regulation at room temperature to 300 degrees.

8. Adjustment convenient: experimental parameters in addition to the aspect ratio,and screw combinations to manual adjustments, Other parameters such as screw speed, temperature, water and pressure can all be set according to need, after the creation of automatic control.

9.Material: SUS.304

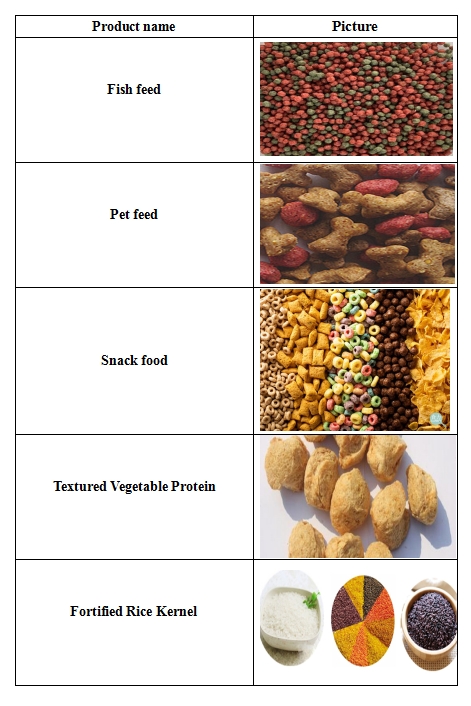

Final product

Service

EACH CLIENT CAN ENJOY THE FOLLOWING 1. Free consultation service before, during, and after sales; 2. Free project planning and design services; 3. Free debugging of equipment until everything is functional; 4. Free management of equipments' long distance shipping; 5. Free training of equipment maintenance and operating personally; 6. Free new production techniques and formulas; 7.We ensure planned preventive maintenance (PPM) at least two times a year and corrective breakdown maintenance whenever required. 8. Provide 2 year warrantee and lifetime maintenance service; |

PRE-SHIPMENT INSPECTION INCLUDES 1.Supplier should trial run whole line at supplier’s factory before shipment; 2.All raw materials for that trial run to be arranged by supplier at their cost. |

INSTALLATION SUPERVISION AND COMMISSIONING 1.The customer will be asked to provide room, board, round-trip transportation, and anominal $100 daily subsidy per person. 2.The total length of the installation time depends on number and qualification of the available local stuff.A possible delay of the installation period will be additionally invoiced. |