Pet chew toy making machine

1. 14 years of experience in the production and export of food products.

2. Provide different product formulations.

3. Warranty for one year, long-term supply of spare parts at reduced prices.

4. Engineers on site installation and commissioning, training of technicians.

5. Provide a professional choice of equipment, technological process, consultations on the design of the plant.

Pet chew toy-making machine. Pet chew takes starch as raw materials with scientific configuration and was extruded from co-extruder, it can be made into different kind of shapes such as stick, bone,bi-color,bi-flavor, etc, this kind of food not only provide protein, fat, vitamin, nutrition for dogs but also satisfy the dog nature hobby. It has the following features; strong teeth, clean mouth, and teeth. The products can be in many shapes, like twists, double colors,core-filling, and so on.

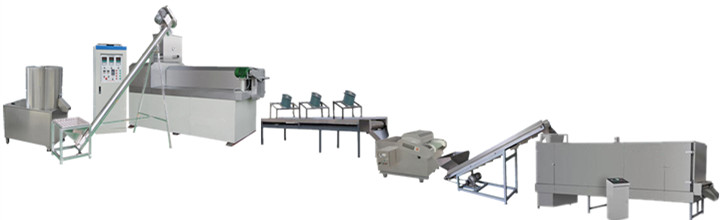

Animal dog cat pet chew toy production line

Flow chart:

Mixer→Screw conveyor→Single screw extruder→Cooling machine→Cutter→Hoister→Dryer

Finished Products:

Main Accessories:

Technical Parameter:

Model | HM100 extruder line | HM120 extruder line |

Installed Power | 99kw | 114kw |

Power Consumption | 75kw | 86kw |

Production Capacity | 80-120kg/h | 100-150kg/h |

Dimension | 19000*2000*2200mm | 27000*2000*2200mm |