Our News

In the production process of dog food, the puffing process is one of the most core parts

2021/12/16 17:18

Jinan Himax Machinery Co., Ltd. is a manufacturer specializing in the production of puffing equipment. Our company’s main equipment includes food puffing machinery, floating sinking fish feed equipment, tissue protein production line, pet food production line, floating fish feed production line, puffed feed production line, Nutritious rice processing equipment, corn artificial rice equipment, modified starch production line, sandwich food production line, puffed snack food production line, fried puffed food production line, corn noodle production line, breakfast cereal production and processing equipment, puffed nutrient powder production line, bread bran puffing machine, etc. Equipment and auxiliary equipment

2021/11/17 11:00

Microwave dryer, microwave drying equipment, microwave oven, microwave puffing equipment introduction:

The safe and reliable microwave shielding design ensures that the microwave leakage is less than 2mw/cm2, which is far better than the national standard;

Compared with traditional drying methods (hot air, steam, electric heating, etc.), microwave drying has the following remarkable characteristics of "high quality, high efficiency, energy-saving, and environmental protection":

①Achieve pollution-free and uniform drying of materials, while drastically reducing the drying temperature;

②The drying speed is usually increased by several times, and the production efficiency is greatly improved;

③Drying energy consumption is usually reduced by more than 50%;

④ Realize safe and clean production.

The safe and reliable microwave shielding design ensures that the microwave leakage is less than 2mw/cm2, which is far better than the national standard;

Compared with traditional drying methods (hot air, steam, electric heating, etc.), microwave drying has the following remarkable characteristics of "high quality, high efficiency, energy-saving, and environmental protection":

①Achieve pollution-free and uniform drying of materials, while drastically reducing the drying temperature;

②The drying speed is usually increased by several times, and the production efficiency is greatly improved;

③Drying energy consumption is usually reduced by more than 50%;

④ Realize safe and clean production.

2021/11/02 16:56

Extruded machinery and equipment have been widely used in the field of raw material pretreatment, and maintenance cannot be ignored. The following aspects must be grasped:

2021/10/29 09:13

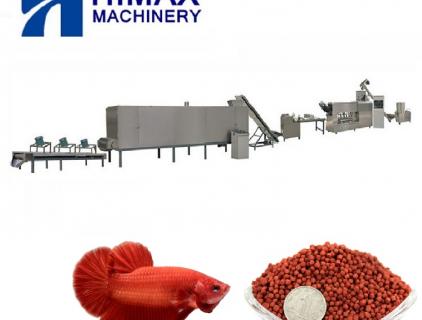

Advantages of extruded feed:1. Improve the utilization rate of feed;2. Reduce environmental pollution;3. Reduce the occurrence of diseases;4. Improve breeding density;5. Extend the storage period of the feed;6. Convenient feeding management;7. It can meet the needs of animals with different feeding habits.

2021/10/13 16:52

Pet Food Extruder Machine,Pet Food Manufacturing Equipment,Pet Food Production Line

2021/09/27 09:19

September Purchasing Festival is coming

2021/08/23 14:53

Kurkure nik naks making machine, are special extruded snacks

2021/03/18 15:31

In the production process of dog food, the puffing process is one of the most core parts

Jinan Himax Machinery Co., Ltd. is a manufacturer specializing in the production of puffing equipment. Our company’s main equipment includes food puffing machinery, floating sinking fish feed equipment, tissue protein production line, pet food production line, floating fish feed production line, puffed feed production line, Nutritious rice processing equipment, corn artificial rice equipment, modified starch production line, sandwich food production line, puffed snack food production line, fried puffed food production line, corn noodle production line, breakfast cereal production and processing equipment, puffed nutrient powder production line, bread bran puffing machine, etc. Equipment and auxiliary equipment

Microwave dryer, microwave drying equipment, microwave oven, microwave puffing equipment introduction:

The safe and reliable microwave shielding design ensures that the microwave leakage is less than 2mw/cm2, which is far better than the national standard;

Compared with traditional drying methods (hot air, steam, electric heating, etc.), microwave drying has the following remarkable characteristics of "high quality, high efficiency, energy-saving, and environmental protection":

①Achieve pollution-free and uniform drying of materials, while drastically reducing the drying temperature;

②The drying speed is usually increased by several times, and the production efficiency is greatly improved;

③Drying energy consumption is usually reduced by more than 50%;

④ Realize safe and clean production.

The safe and reliable microwave shielding design ensures that the microwave leakage is less than 2mw/cm2, which is far better than the national standard;

Compared with traditional drying methods (hot air, steam, electric heating, etc.), microwave drying has the following remarkable characteristics of "high quality, high efficiency, energy-saving, and environmental protection":

①Achieve pollution-free and uniform drying of materials, while drastically reducing the drying temperature;

②The drying speed is usually increased by several times, and the production efficiency is greatly improved;

③Drying energy consumption is usually reduced by more than 50%;

④ Realize safe and clean production.

Extruded machinery and equipment have been widely used in the field of raw material pretreatment, and maintenance cannot be ignored. The following aspects must be grasped:

Advantages of extruded feed:1. Improve the utilization rate of feed;2. Reduce environmental pollution;3. Reduce the occurrence of diseases;4. Improve breeding density;5. Extend the storage period of the feed;6. Convenient feeding management;7. It can meet the needs of animals with different feeding habits.

Pet Food Extruder Machine,Pet Food Manufacturing Equipment,Pet Food Production Line